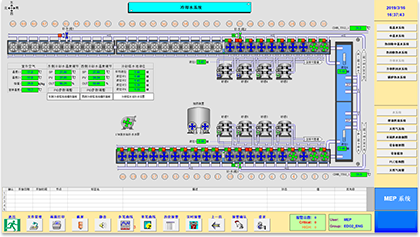

The energy center is the core device and power source of the production enterprise. It provides chilled water, hot water and compressed air for the process production. It is the basis of stable production. Its automatic control system needs to fully consider the system stability and meet the energy saving requirements. How to make each subsystem run well, ensure high-quality production, reduce maintenance downtime as much as possible, and use less manpower to achieve good management and operation, so as to create the maximum economic benefits for the enterprise. Combining with many years of practical experience in industrial automation, we have put forward an automatic control solution based on the energy center to realize the production of cold water, hot water, compressed air, etc Equipment monitoring and management.

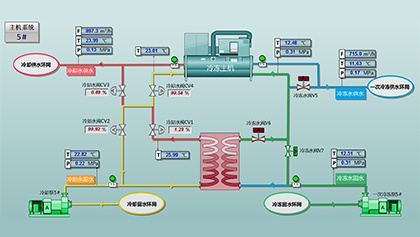

The power plant needs to effectively start and stop the chiller, water pump, hot water boiler, plate exchange and other equipment, directly monitor and manage them to meet the downstream users' demand for cold and hot water, and realize effective energy saving. In addition, it involves communication with more subsystems to achieve more data interaction, mainly including: water chiller, boiler system, dosing system, degassing system, constant pressure system, etc.