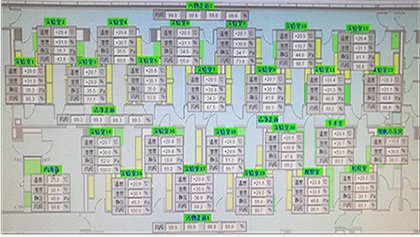

With the increasing investment in medical research and development in China, there are more and more laboratory projects, and the requirements of the laboratory for cleaning, pressure, ventilation and airflow are different, which meet different design requirements, while ensuring the stability and flexibility of the automatic control system. Combining with many years of practical experience in the industry, we have launched a solution based on laboratory automatic control to realize a variety of practical applications Monitoring and management of laboratory production and equipment.

Objective: to establish an orderly airflow direction, ensure the airflow from high cleanliness to low flow, reduce and isolate cross contamination. According to the specific needs of ventilation, the differential pressure control scheme is formulated to meet different needs. Make logical interlock and standby scheme according to process conditions.

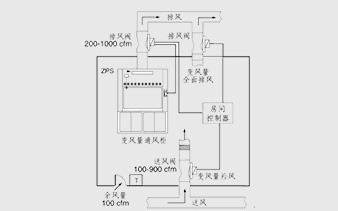

Objective: to inhibit the harmful chemical gas produced in the fume hood, prevent its leakage, and discharge it out of the laboratory as soon as possible, so as to protect the safety of the laboratory staff. When the regulating door of the fume hood is in any position, the wind speed on the regulating door of the fume hood shall be kept constant. The national standard is 0.4 ~ 0.6 m / s.